Beschreibung

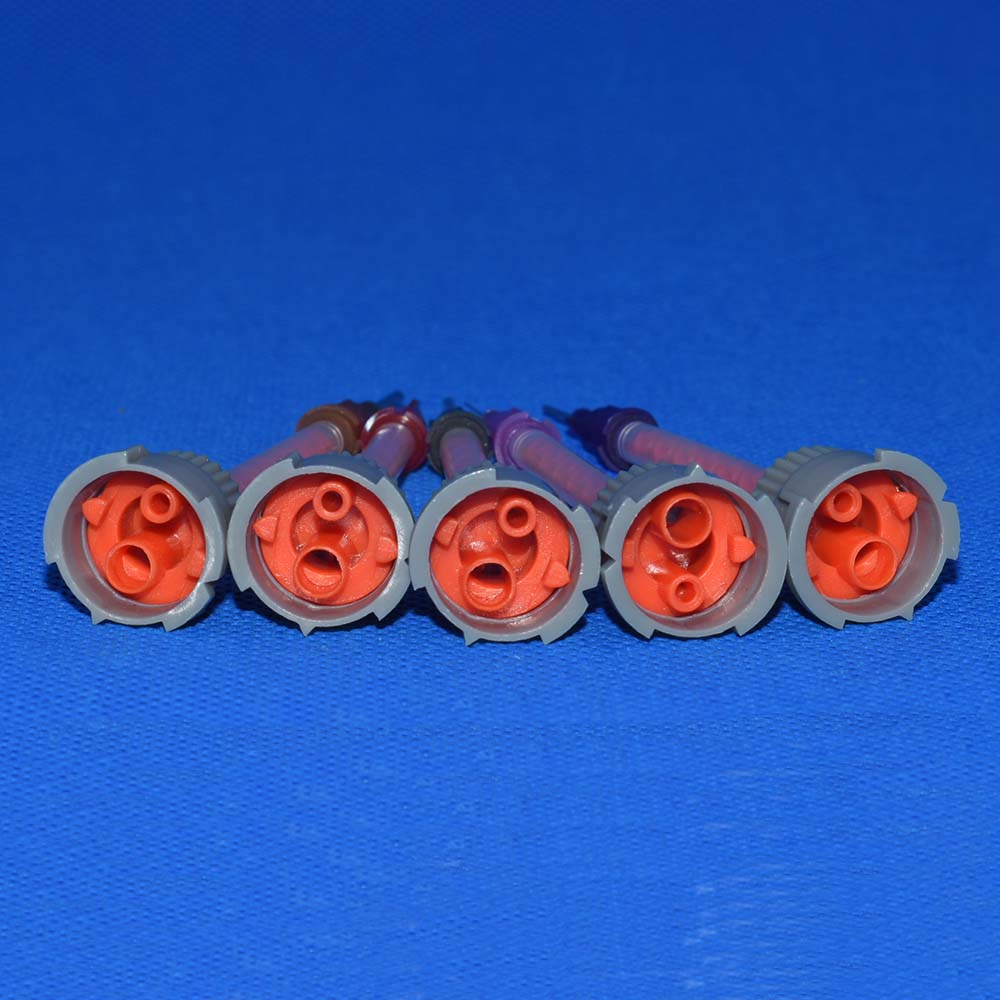

The Mixing Tube 3.2-16L 10:1 is a cutting-edge solution engineered for precise blending in static mixing systems. With a specific mixing ratio of 10:1, the tube is crafted to deliver unparalleled accuracy and consistency in various applications, ranging from adhesives and sealants to coatings and beyond.

Parameter:

Mischverhältnis: 10:1

Material: PP, POM

Gesamtlänge: 73Millimeter

Innendurchmesser: 3.2Millimeter

Außendurchmesser: 4.8Millimeter

Entladekaliber: 2Millimeter

Key Features:

Precision Mixing:

The tube’s meticulously designed geometry ensures the thorough and uniform blending of two components at a precise 10:1 Verhältnis. This level of accuracy is crucial for applications where the performance is directly influenced by the proportion of mixed materials.

Static Mixing Efficiency:

Tailored for static mixing systems, the Tube 3.2-16L eliminates the need for dynamic mixing equipment. Its innovative design allows for efficient blending as the components pass through the tube, simplifying processes and reducing the risk of inconsistent mixtures.

Versatility:

Suitable for a diverse range of materials, including adhesives, Harze, and coatings. The Tube 3.2-16L’s versatility makes it a go-to choice for industries requiring reliable and controlled mixing in their applications.

Robust Construction:

Crafted from high-quality materials, the mixing tube exhibits durability and resistance to wear, ensuring a long operational life. This robust construction contributes to the tube’s reliability in demanding industrial environments.

Easy Integration:

Designed for seamless integration into existing static mixing systems, the Tube 3.2-16L offers ease of use and installation. Its compatibility with standard equipment makes it a convenient choice for upgrading or enhancing mixing capabilities.

Anwendungen:

Adhesive Bonding

Sealant Dispensing

Coating Processes

Resin Mixing

Chemical Blending

English

English العربية

العربية Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch עברית

עברית Italiano

Italiano 日本語

日本語 한국어

한국어 Norsk

Norsk Polski

Polski Português

Português Русский

Русский Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Bewertungen

Es gibt noch keine Kommentare.