Electronic component three anti adhesive vibration, insulation, anti-adhesion

After the SMT soldering process, in order to make the components anti-vibration, insulation, anti-glare, especially for coil components, it must be fixed and sealed. It is also necessary to use an adhesive that acts as a positioning seal. The positioning sealant should have the following characteristics:

1, the appropriate viscosity, easy to sizing operation.

2, moisture-proof, anti-vibration, good insulation performance.

3, the surface drying time should not be too short, usually about 30min is appropriate, in order to facilitate the adjustment of components such as coils during this period.

4, according to the needs of the product, sometimes need to use a fully cured adhesive, and sometimes need to use a self-adhesive type to facilitate the replacement and repair of components.

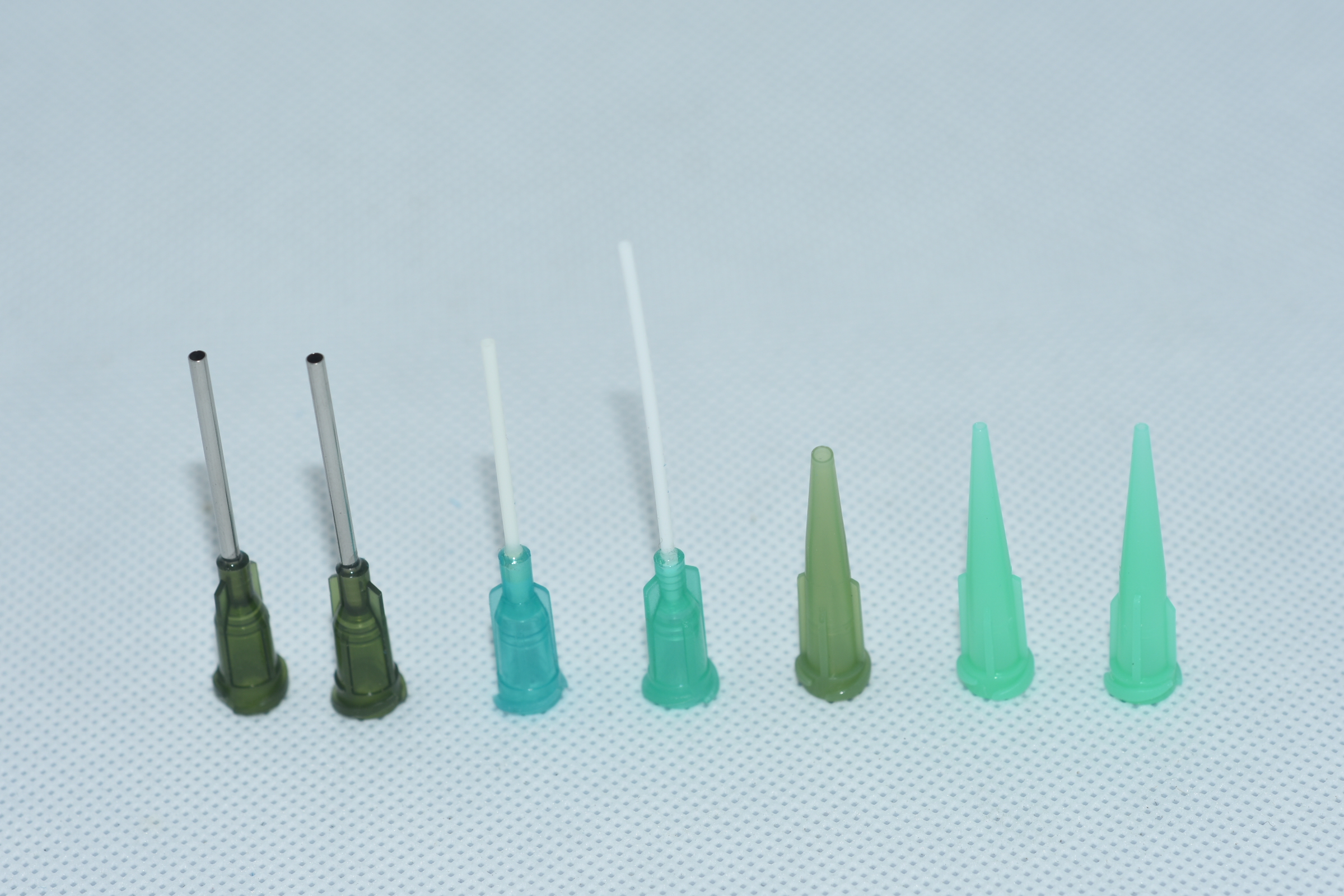

Electronic component three anti adhesive is various synthetic rubbers and polyesters that can be used as adhesives for positioning sealants. These rubbers have high cold resistance, air tightness and electrical insulation, and high bond strength and elongation. These glues are used for positioning and sealing. The glue should be formulated into a solvent-based adhesive when used. When the viscosity changes, it can be diluted with a solvent at any time. When applying glue, hand-coating is carried out using a pneumatic injection device and a watering can, a brush or a brush.

However, because such glues contain solvents, which are harmful to the atmosphere and the human body, there is a tendency to be replaced by RTV organic silica gel. As a positioning seal, a one-component room temperature vulcanized silicone rubber is used, which has good electrical insulation. Adhesive, plastic cylinder packaging, can be directly sized.

English

English العربية

العربية Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch עברית

עברית Italiano

Italiano 日本語

日本語 한국어

한국어 Norsk

Norsk Polski

Polski Português

Português Русский

Русский Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe