The mixing effect of the square mixing nozzle is 2 times that of the round mixing nozzle.

The square of MC06-24 mixing nozzle is divided into 4 parts. The round of MC06-48 mixing nozzle is divided into 2 parts.

As the liquid passes through, it is continuously divided and thus mixed.

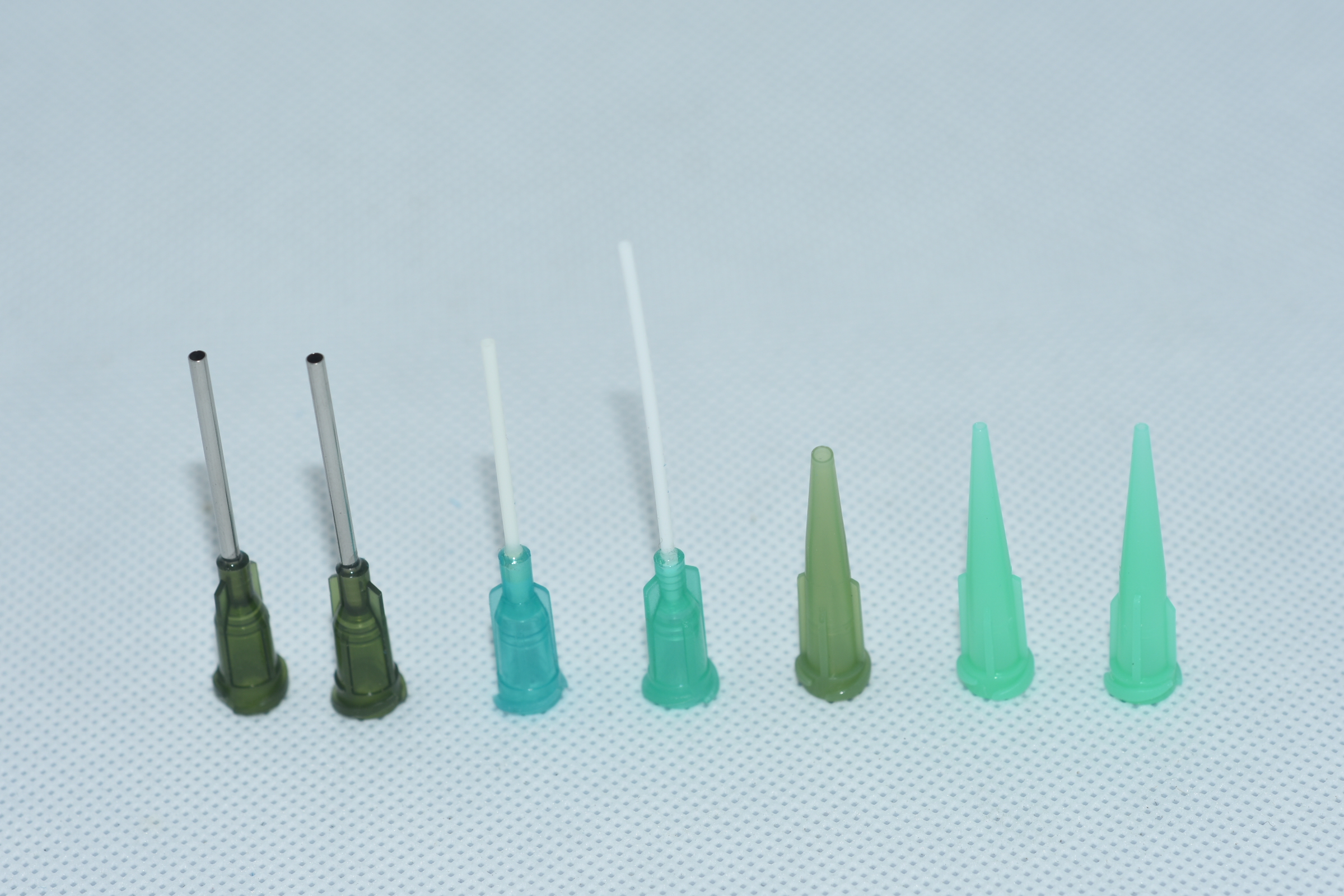

For square MC06-24 mixing Nozzle and round MC06-48, their nozzle are appro 1.5mm.

Square MC06-24 mixing nozzle parameter:

Outside diameter: 7.6MM

Inner diameter: 5.3MM

Length: 127MM

Section number: 24

Glue caliber: 1.5MM

English

English العربية

العربية Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch עברית

עברית Italiano

Italiano 日本語

日本語 한국어

한국어 Norsk

Norsk Polski

Polski Português

Português Русский

Русский Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe