Dental adhesive filling caries cavity type and related applications

Dental adhesive denture soft lining material, also known as elastic denture lining expansion material for filling, is used for tooth-based tissue bonding. It can cushion the bite force and evenly transmit the bite force to the alveolar ridge, thus reducing or eliminating toothache. . Denture base resin is PMMA, which is a rigid organic resin. It is made by adding methyl methacrylate solution of terminal hydroxyl group to diene polyurethane to the initiator system and photoinitiator. The visible solid-state adhesive can be made after coating. After being irradiated with a visible light curing machine for about 90 seconds, the soft lining material and the adhesive can be cured to make it adhere.

Dental adhesive The methacrylic filling material of the caries cavity has been rapidly developed for filling in recent years, and many new and better varieties have appeared. This type of filling adhesive is characterized in that the cured product has the same color tone as the tooth surface, high compressive strength (about 200-300 MPa), no saliva, strong bonding strength with dentin, and the like. The disadvantage is that the performance of the hanging grinding is poor, and there is a certain harmful effect on the pulp due to residual monomers. In addition, color change caused by the addition of a normal temperature polymer initiator is also a problem.

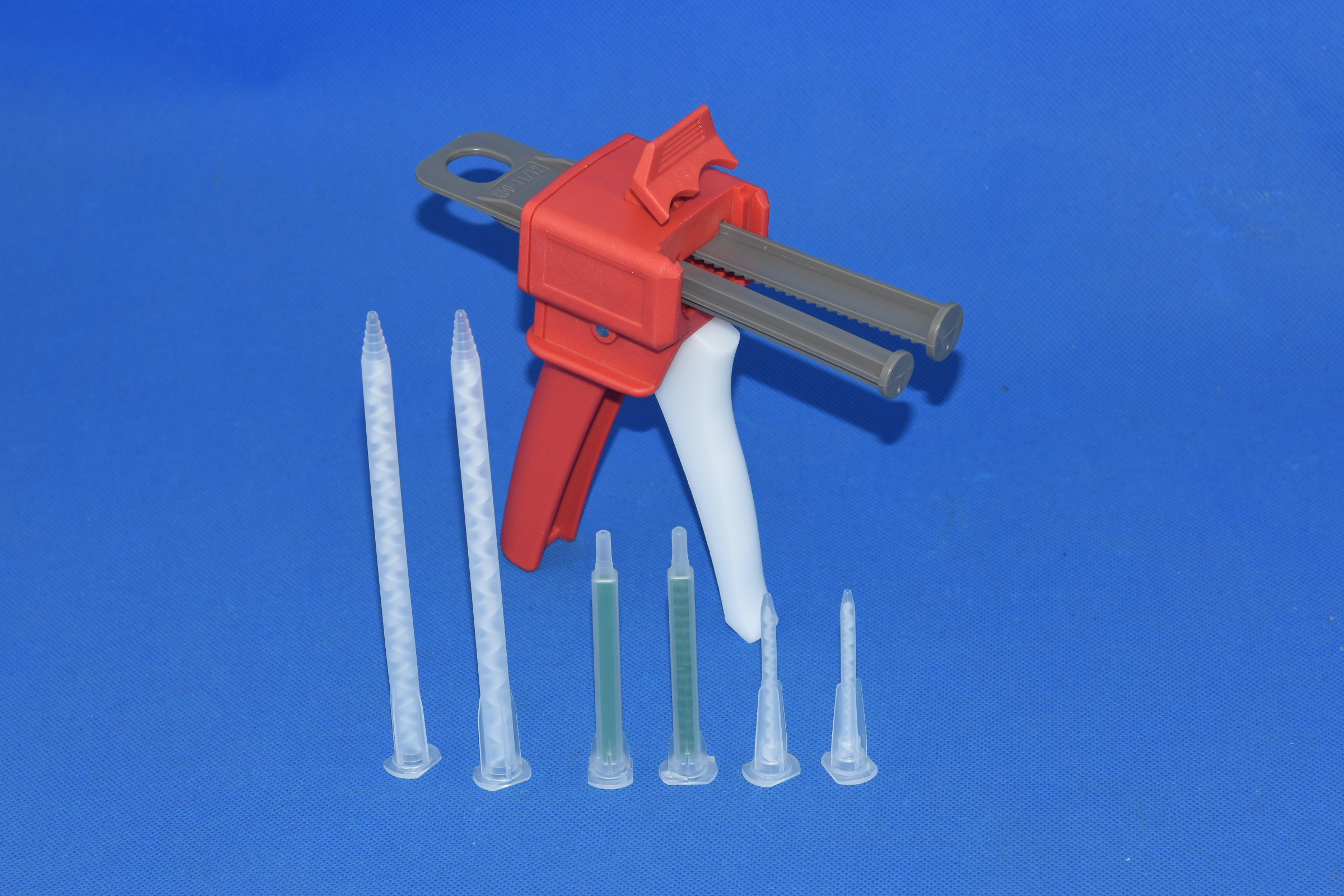

There are 2 types of dental adhesive for filling. One of them is a methyl methacrylate-based composite resin composed of a methacrylic acid monomer and a polymer thereof and a fine glass powder, which is cured by tri-n-butyl boron and a redox system normal temperature polymerization initiator. The second one is a condensate of bisphenol A and glycidyl methacrylate, and 70%-80% by mass of quartz powder or special glass powder is added thereto to prepare a high-viscosity paste, and benzoyl peroxide is used. Or a tertiary amine redox system is allowed to cure at room temperature by a polymerization initiator. Due to its high viscosity, it is used by applying a low-viscosity pretreatment agent to the tooth surface treated with phosphoric acid and washed with water to form a thin coating, which is then coated with bisphenol A methyl methacrylate. a condensate of glycerides. This pretreatment agent is a condensate of bisphenol A methacrylic acid glycidyl ester diluted with a dimethacrylate monomer by a methacrylate monomer to which a conjugate is added.

The effect of dental pit and fissure sealing technology (ART) anti-caries has been recognized by everyone. Longqi has a significant pre-effect on the running-in surface, and it can make up for the insufficient effect of fluoride on the pit and sulcus. More significant. The operation process is as follows: wash the residue in the pit and groove, wash with a cleaning solution, then scrub with water, dry the dry cotton ball, mix the glass ion cement (Katac-motar, ESPE) according to 1:1 ratio, confiscating After mixing evenly, press the finger into the joint gap and the crack, and use the hand-held instrument to remove the excess glass ion material. Note that the cotton should be wetted and disinfected during the whole process.

The method of constructing tissue engineering cartilage by using polyhydroxybutyrate scaffold is used for the construction of human tissue engineered bone, and the repair of cartilage defect has also been reported.

English

English العربية

العربية Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch עברית

עברית Italiano

Italiano 日本語

日本語 한국어

한국어 Norsk

Norsk Polski

Polski Português

Português Русский

Русский Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe